HVAC Systems: The Invisible Heroes in Our Industrial Air Quality

In the dynamic world of industrial environments, air quality management often takes the backseat, overlooked in the hustle of production. But if there's one element that ensures the invisible health of an industrial facility, it is the HVAC system. When a space teems with machinery, chemicals, and the continual movement of people, maintaining air purity becomes critical. From managing temperature to removing pollutants, industrial HVAC systems function as the unsung heroes safeguarding the health and productivity of the workforce.

In this comprehensive exploration, we dissect the role of HVAC systems in industrial settings, understand the significance of air quality, and provide valuable insights into how these systems can be optimized to enhance overall operational efficiency.

The Anatomy of Industrial Air Quality

Why Air Quality Matters

In the industrial domain, the air that operatives breathe is not just a comfort; it's a lifeline. Contaminants such as dust, fumes, gases, and aerosols are commonplace and can lead to a variety of health issues, ranging from respiratory problems to chronic diseases. Even when the threat isn't immediately visible, the long-term impact on workforce health and absence rates can be substantial.

Understanding the Risks

Industrial byproducts like volatile organic compounds (VOCs) and particulate matter pose a significant health risk when inhaled. Some manufacturing processes can release dangerous agents such as carbon monoxide, which, in high concentrations, can be lethal. The key is not to eliminate these byproducts entirely (which is often unfeasible) but to manage their concentration within safe limits—a task that falls squarely on the shoulders of HVAC systems.

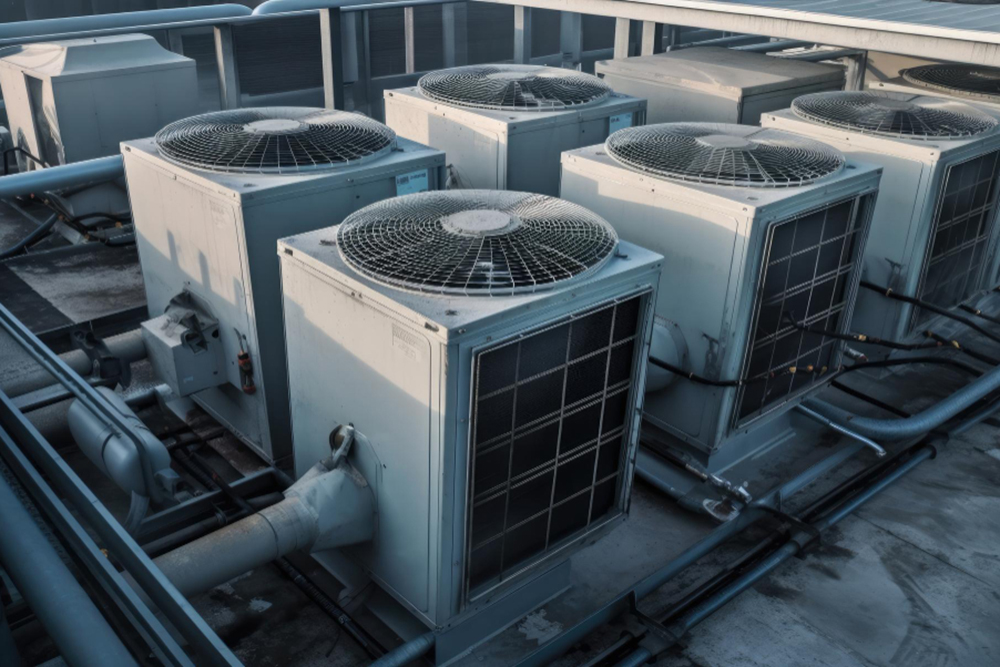

HVAC Systems as the Lungs of the Industry

The Basics of Industrial HVAC

Industrial heating, ventilation, and air conditioning (HVAC) systems are enormous frameworks woven intricately into the fabric of production facilities. From the smallest of fan units to large-scale chillers, these systems work together to ensure a conducive environment for both human and machine.

Temperature Control

One of the primary functions of an industrial HVAC system is temperature regulation. Whether it’s maintaining a consistent heat level to prevent thermal shock to delicate equipment or cooling a space where heat-intensive processes occur, accuracy and reliability are non-negotiable.

Humidity's Stealthy Role

Controlled humidity plays a nuanced, but critical part in maintaining air quality. Too much moisture in the air can lead to surface corrosion on machinery and can be a breeding ground for molds. On the other hand, extremely dry air can cause electrostatic discharge, jeopardizing both worker safety and product integrity.

Air Distribution and Ventilation

By effectively distributing filtered air throughout the industrial space, HVAC units combat the stagnation of air and the build-up of contaminants. Proper ventilation is also crucial in high-heat areas, ensuring a circulation that helps in the management of internal temperatures.

Enhancing Air Quality through HVAC Optimization

The Power of Filtration

Upgrading filtration systems to capture finer particles and implementing regular maintenance schedules can significantly improve air quality. High-efficiency particulate arrestance (HEPA) filters, for example, are known for their superior capabilities in trapping microscopic contaminants.

Specialized HVAC for Hazardous Environments

Certain industries require HVAC systems with specialized features, such as those that comply with standards for explosiveness and dust concentration. These custom systems are designed to not only maintain air quality but also ensure that the environment remains safe for operations.

Routine Inspections and Upkeep

Preventive maintenance is the bedrock of system optimization. It involves regular inspections, adjustments, and part replacements to pre-empt potential malfunctions. Not only does this extend the lifespan of HVAC equipment, but it also ensures that air quality remains at its best.

The Technological Advancements in Industrial HVAC

The March of Digitalization

The advent of Internet of Things (IoT) has paved the way for 'smart' HVAC systems that can be remotely monitored and controlled. This not only allows for swift adjustments in response to changes but also facilitates data gathering and analysis, leading to more informed decision-making.

Energy Efficiency

The push for sustainability and reduced energy consumption has led to innovations in HVAC technology. Advancements in energy recovery ventilation systems enable a transfer of energy between outgoing and incoming air, leading to substantial energy savings in environments where constant air exchange is necessary.

Choosing the Right HVAC Supplier for Your Industrial Needs

Key Considerations in Selection

Choosing the right HVAC supplier is a decision that carries long-term implications. It's essential to consider factors such as the supplier's track record, the range of products and services offered, and their responsiveness to client needs.

Partnering for Success

Selecting a supplier who not only provides equipment but offers maintenance and support services can be highly advantageous. Partnering with such a supplier ensures that best practices are observed in the installation and upkeep of HVAC systems, leading to an extended and effective service life.

For Florida Industries

For businesses within the Sunshine State, navigating the complex landscape of industrial air quality management can be simplified by reaching out to a reliable HVAC supplier such as Discount Air Supply. With a commitment to excellence and in-depth knowledge of regional industrial needs, they can be the partner you've been searching for to secure your facility’s air quality.

In conclusion, HVAC systems in industrial settings are much more than temperature regulators and air circulators. They are the custodians of air quality, which is pivotal in maintaining a healthy and productive work environment. By understanding the substantial influence HVAC systems wield and by strategically leveraging the advancements in technology, industries can not only comply with health and safety regulations but also ensure the longevity and efficiency of their operations. If air quality is the lifeblood of any industrial space, then HVAC systems are its pulse—steady, regulated, and vital.

With a diligent approach to air quality through your HVAC system, your industrial arena can be not just a great place to work, but a safe one too. It's time to give your invisible heroes a standing ovation.